Singapore’s Nanyang Technological University (NTU Singapore) is developing a rapid prototype for ultra-thin, stretchable electronics that detect bioelectrical signals from skin, muscles, and organs and transmit these signals to control robots and other electronic devices. We have established a high-tech pilot lab with typing capabilities.

When attached to limbs or the head, these smart sensors can help prevent limb disabilities and mobility impairments by providing an accessible way to control robotic prosthetics, machines, and power wheelchairs using alternative muscle movements and biosignals. can empower a person, NTU Singapore said in a paper. Wednesday’s statement.

Citing information from the United Nations, NTU Singapore said that approximately 15 per cent of the world’s population lives with some form of disability1.

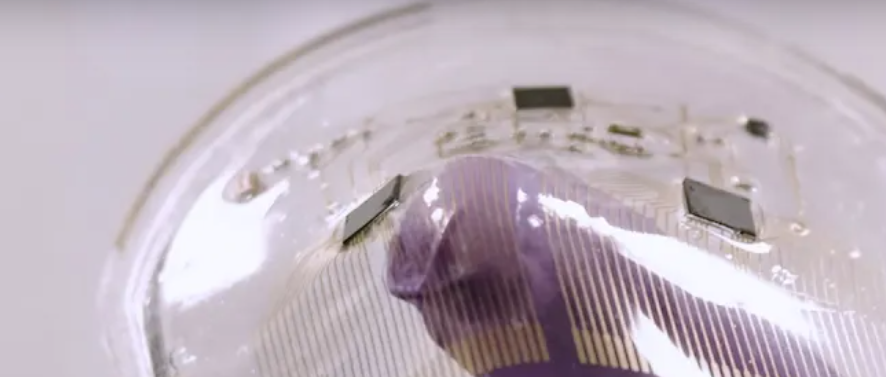

NTU researchers developed these innovative soft electronic devices by combining in-house designed soft materials and processes with commercially available hardware components.

This hybrid combination will allow the NTU team to integrate different types of sensors on the market, including wireless connectivity, accelerometers, temperature sensing, and critical monitoring such as heart rate, blood pressure, and oxygen levels.

Encased in gel-like skin, the sensor is soft, flexible, and stretchable, similar to silicone bandages used in medicine.

These sensors stick to the skin, allow joint movement, and come in a variety of sizes and thicknesses, from centimeters to submicrons (thinner than the width of a human hair (0.01 millimeter)).

“We aim to address some of humanity’s most pressing challenges, from climate change to medical advances.

“My goal is to establish a new center of excellence in soft electronics and build a team of industry experts and commercial partners to bring these technologies to market quickly.” said Professor Chen Xiaodong, Singapore Chancellor’s Professor of Materials Science and Engineering. Director of the Flexible Device Innovation Center (iFLEX).

To begin the scale-up process, Professor Chen established a pilot lab aimed at co-developing and producing soft electronic devices with industry partners, including small and medium-sized enterprises (SMEs).

Through the joint project, he hopes to establish industry standards that will facilitate the mass production of soft electronics in the future and develop the expertise needed for this emerging industry.

Supporting this vision is the NTU Innovation and Entrepreneurship Initiative, launched last March.

As a pillar of the NTU 2025 five-year strategic plan, this initiative aims to accelerate the transition from research to commercialization for faculty and students, providing mentorship and industry insights.

“In today’s fast-paced global market, accelerating disruptive innovation is not just an advantage, it is a necessity to maintain global leadership. It demonstrates Singapore’s role.

NTU Vice-Chancellor (Innovation and Entrepreneurship) Professor Lewis Fee said: “Professor Chen Xiaodong’s innovations at a world-class materials science university6 are a testament to Singapore’s determination to become a leader in science and technology. It is a testimony.”

It should be noted that traditionally, semiconductor manufacturing produces electronics that rely on silicon as the primary substrate or platform. However, silicone is hard and stiff.

Instead, soft electronics uses soft platforms such as stretchable and flexible hydrogels and biocompatible plastics. For these platforms, NTU materials scientists have invented numerous formulations.

To enable electronic circuits to accommodate movement without breaking under repeated stress, these circuits use intricate micro- and nanoscale patterns that are approximately 10 times thinner than the width of a human hair. and printed on a soft substrate.

One such pattern developed by Professor Chen’s team is a wavy ribbon shape for soft electronics, which allows it to be stretched without breaking.

Another of his innovations is “BIND”. This is a soft, stretchy, “Lego-like” universal connector 7 that joins flexible electronic devices by simply pressing them together.

It can withstand stretching up to 7 times its length and is 60 times stronger than traditional connectors.

Together, these patent-pending technologies allow traditional hardware chips to be implemented in combination and connected to resistors and capacitors via printed circuits.

It is notable that Singapore’s economy is heavily dependent on the manufacturing industry, accounting for 22% of gross domestic product (GDP) in 2021.

Advanced electronics manufacturing and innovation, including the fast-growing field of soft electronics, is recognized as a key pillar of the country’s economic development.

Going forward, Professor Cheng is dedicated to establishing Singapore as a cutting-edge research and manufacturing hub for soft electronics, with the Research, Innovation and Enterprise (RIE) plan being the cornerstone of Singapore’s transformation into a knowledge-based society. is seeking support. Innovation-driven economy and society.

OceanBase signs agreement with NTU Singapore for advances in database optimization and green computing