Oulu Energy plans to build a 100 megawatt (MW) hydrogen production plant in Oulu, northern Finland.

The project planning partner is the Finnish company P2X Solutions, which is currently building a hydrogen production plant in Harjavarta in western Finland.

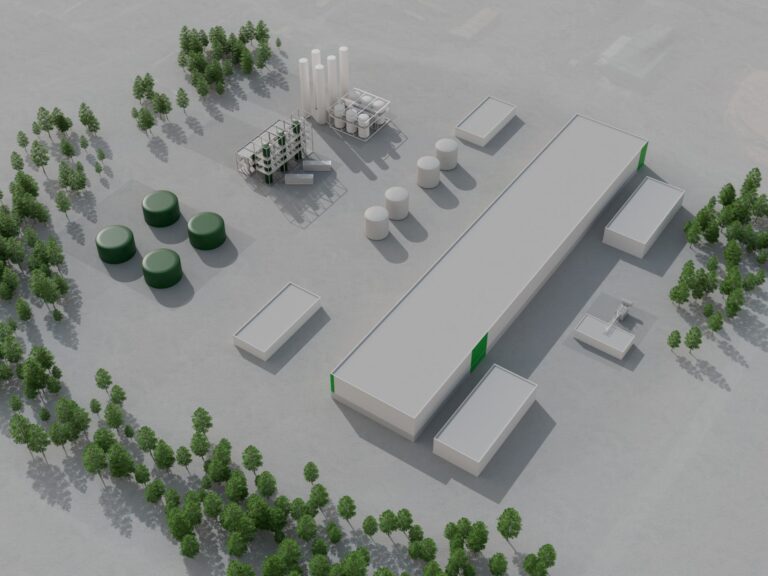

According to preliminary plans, the entire project planned for the La Anila industrial zone includes an electrolysis plant with a capacity of up to 100 MW, a carbon capture plant, hydrogen and carbon dioxide storage facilities, and a further processing plant capable of producing finished products. It is said that there are plans to do so. For example, methane and methanol.

This is Oulu Energy’s first hydrogen project and is also significant on a European scale.

The products produced by hydrogen plants could potentially be used to replace fossil fuels in road, sea and air transport.

Preliminary estimates suggest that approximately 200 to 400 gigawatt hours (GWh) of thermal energy per year will be generated as a byproduct and sent to district heating networks, while oxygen could be recovered for industrial use.

“The resulting thermal energy corresponds to approximately 10-30% of Oulu’s annual district heating demand. This makes it possible to produce heat in an environmentally friendly way, increasing the competitiveness of district heating. ” said Kimmo Alaturkila, Development Director at Oulu Energy.

“Oulu Energy is a pioneer in sustainable energy production in northern Finland. We are very happy to be working on a joint project that shows that green hydrogen can also be a solution for reducing emissions through heat generation.

“Once completed, the Oulu hydrogen plant will have a capacity of up to 100 MW, making it very significant on a Finnish scale. For P2X Solutions, this project will significantly expand the operations of our facility in Harjavarta. “Joensuu,” says Herco Pritt, CEO of P2X Solutions.

Additionally, the project aims to investigate the possibility of recovering biogenic exhaust gases from local industries and power plants in the further processing of hydrogen.

During the project development phase, plant feasibility and location options are considered and an impact assessment is performed.

An investment decision is expected to be made in the fall of 2025, and the factory could be completed as early as 2028.

The project planning partner is the Finnish company P2X Solutions, which is currently building a hydrogen production plant in Harjavarta in western Finland.

According to preliminary plans, the entire project planned for the La Anila industrial zone includes an electrolysis plant with a capacity of up to 100 MW, a carbon capture plant, hydrogen and carbon dioxide storage facilities, and a further processing plant capable of producing finished products. It is said that there are plans to do so. For example, methane and methanol.

This is Oulu Energy’s first hydrogen project and is also significant on a European scale.

The products produced by hydrogen plants could potentially be used to replace fossil fuels in road, sea and air transport.

Preliminary estimates suggest that approximately 200 to 400 gigawatt hours (GWh) of thermal energy per year will be generated as a byproduct and sent to district heating networks, while oxygen could be recovered for industrial use.

“The resulting thermal energy corresponds to approximately 10-30% of Oulu’s annual district heating demand. This makes it possible to produce heat in an environmentally friendly way, increasing the competitiveness of district heating. ” said Kimmo Alaturkila, Development Director at Oulu Energy.

“Oulu Energy is a pioneer in sustainable energy production in northern Finland. We are very happy to be working on a joint project that shows that green hydrogen can also be a solution for reducing emissions through heat generation.

“Once completed, the Oulu hydrogen plant will have a capacity of up to 100 MW, making it very significant on a Finnish scale. For P2X Solutions, this project will significantly expand the operations of our facility in Harjavarta. “Joensuu,” says Herco Pritt, CEO of P2X Solutions.

Additionally, the project aims to investigate the possibility of recovering biogenic exhaust gases from local industries and power plants in the further processing of hydrogen.

During the project development phase, plant feasibility and location options are considered and an impact assessment is performed.

An investment decision is expected to be made in the fall of 2025, and the factory could be completed as early as 2028.